A look at the rotary piston flow meter range and how the range of flow meters work.

Positive displacement flow meters, also known as PD meters, measure volumes of fluid flowing through by counting repeatedly the filling and discharging of known fixed volumes. A typical positive displacement flowmeter comprises a chamber that obstructs the flow. Inside the chamber, a rotating/reciprocating mechanical unit is placed to create fixed-volume discrete parcels from the passing fluid.

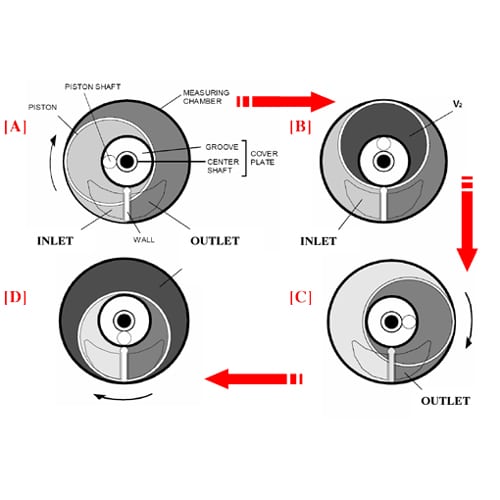

In the VFF, the rotor is basically a disc shape with an annular groove on its underside, capable of holding and transporting flow from the chamber inlet to the outlet. Some fluid is also transported in a cavity formed between the rotor outside wall and the chamber wall.

A centre ‘peg’ under the rotor is constrained to run in a circular groove in the body. A web (or plate) in the body is engaged with a slot in the rotor and this modifies the rotation to that of an oscillation as flow passes. It is this oscillation that produces the compartmentation of the fluid into ‘positively displaced pockets’.

At the top of the rotor, there is a powerful magnet positioned directly above the “peg” located on the underside. The peg follows a circular path, enabling it to interact with a reed switch sensor located in the top cap. This interaction results in the engagement and disengagement of the sensor. For every oscillation, a volt-free contact closure output signal is produced, representing a precise volume increment.

The fluid is transported in a ‘positive’ manner at all times. The typical metering repeatability is better than 0.2% and a meter accuracy of 1% actual reading is usually obtained over a substantial flow range. For lowest flows the meter will under-read the actual flow in a consistent manner. This allows an improved wide-range system accuracy to be gained by the use of a linearising electronics instrument.