Litre Meter supplies a range of flow meters for Oil & Gas applications. For quantity orders, they specialise in customising a range of flowmeters to meet specific customer requirements. A good example of this is flow meters for subsea use, i.e. with the ability to work subsea and transmit a flow signal to the surface. The first example (from 2010) shows a subsea hydraulics flowmeter which uses many of the custom attributes of the VFF series of rotary piston positive displacement meter.

A subsea VFF showing 5 degrees of customisation (from 2010)

Litre Meter describes six degrees of customisation, and the example above has 5:

- Connections – in this meter, the connections were direct to the customer’s manifold (at the base)

- Materials – 316 stainless, which is standard for VFF – the only missing degree…

- Flow Range – This series included 16 meters with unique calibration ranges.

- High Pressure – these were a mixture of 760 and 520 bar

- Communication – these were provided with RS-485; CiA443 is now available

- Subsea – Working up to 300bar external

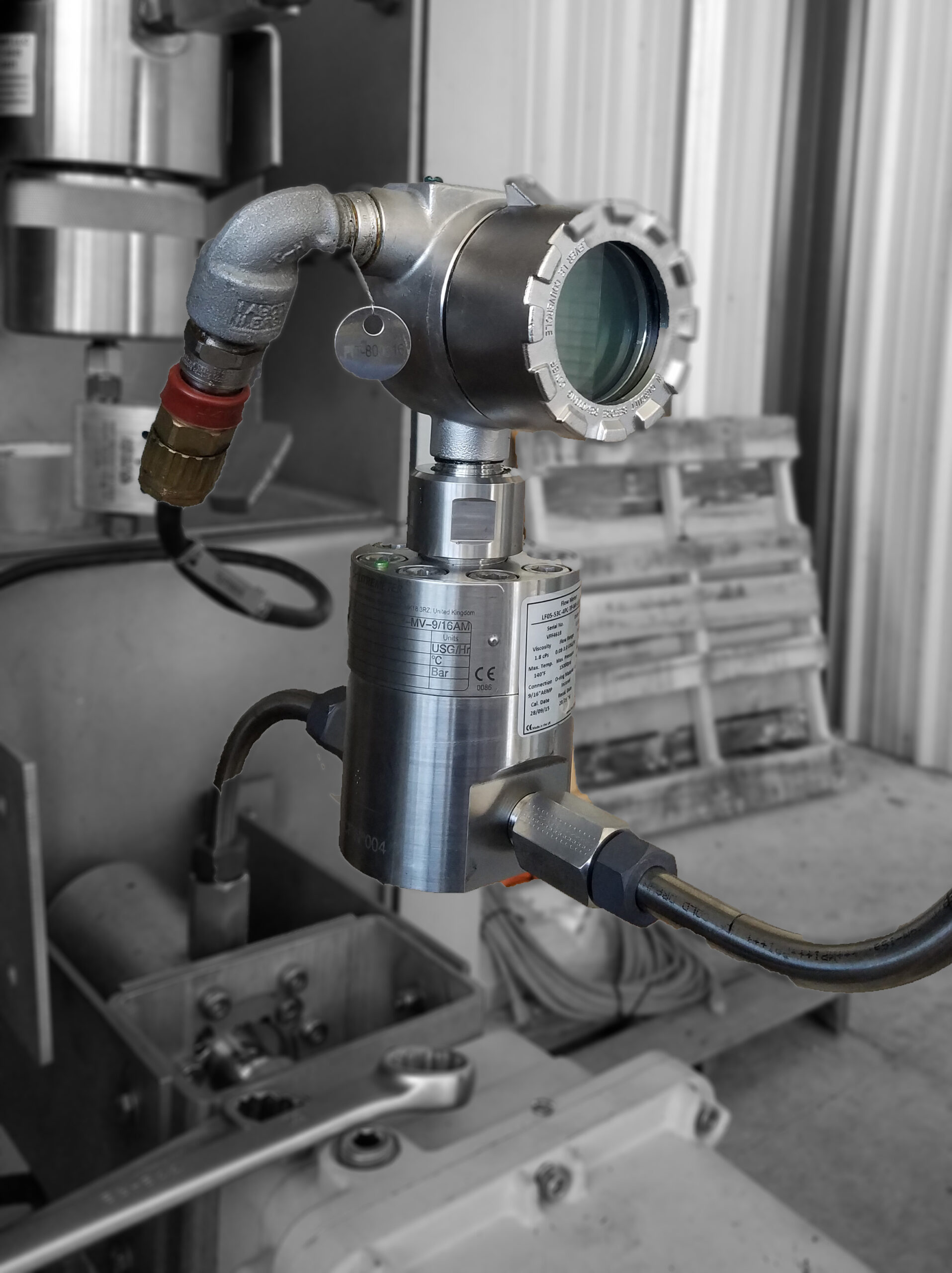

A 2018 VFF Flowmeter showing the compactness of the FlowPod display.

This has 5, albeit different, degrees of customisation: High pressure, special connections, communication, low flow, and flow range.

- Connections – in this meter, Autoclave Engineers Medium Pressure connections were specified

- Materials – normally 316 but Duplex S32750 (F53) was selected

- Flow Range – This series included 51 meters, with PVD coating, removable PBCs and special calibration ranges.

- High Pressure – most were 1035 bar/15,000 psi/15ksi

- Communication – The current FlowPod versions offer HART 7.

- Subsea – The only missing degree…

PBC

The Pressure Balanced Chamber (PBC) is used to isolate the measuring element from the pressure vessel purpose of the VFF. This allowed optimised materials for the rotor and chamber – to give better flow range, for example, and simultaneously enabled the use of more exotic materials for the pressure vessel. Many more units have been constructed in duplex and super duplex, which would have proved almost impossible to use for measurement surfaces (due to the tolerances of manufacture).

PVD

When Litre Meter separated the meter into two functions of measurement and pressure containment, the use of coatings could be exploited. After careful selection and testing, all of the VFF range are now supplied with PVD coating. This remarkable addition enables both higher and lower flow rates. For example, the LF15 size was rated to 45 l/hr maximum. Typically, without coating, the stainless steel rotor could measure down to 5 l/hr on water (the hardest fluid to measure for a positive displacement device). With the PVD coating, the coefficient of friction is reduced, the minimum flow rate reduces to 1 l/hr, and the added hardness enables over-range up to 90 l/hr.